TLC Plates (Thin Layer Chromatography)

Rediscover the Power of Thin Layer Chromatography Using TLC Plates

TLC Plates (thin layer chromatography) might be one of the most undervalued methods of chromatographic analysis for the separation and identification of chemical substances.

TLC Plates (thin layer chromatography) might be one of the most undervalued methods of chromatographic analysis for the separation and identification of chemical substances.

Thin Layer Chromatography provides:

- Rapid results and inexpensive operation

- Qualitative data for compound identification and purity

- The ability to monitor the progress of chemical reactions

- Aid in developing optimal methods

- Quantitative data with the proper instrumentation

Benefits of TLC

TLC is the chromatographers’ fast-lane choice for:

- Ultra-fast solvent and gradient optimization prior to HPLC

- Determining the number of major compounds present in a mixture

- Quick assessment and monitoring of both biotransformations and synthetic reactions

- Choosing the appropriate solvent system for column and flash chromatography

- Simultaneous analysis of several samples under identical conditions

Enhanced quality control & extensive product portfolio

Our TLC plates are manufactured with stringent production controls. TLC layers are smooth, homogenous, uniform, and reproducible from plate-to-plate and lot-to-lot.

Expand your method applications with our comprehensive selection

- Silica gel, alumina, or bonded phases

- With or without UV254 indicator

- Glass, plastic, or aluminum backings

- In a variety of sizes from 20 x 20cm to 2.5 x 7.5cm

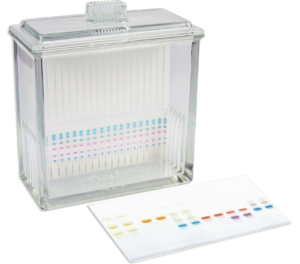

Sorbtech Rocket – Small-Scale TLC Development Chamber

Method for Conditioning TLC Plates

A conditioning method is used to ensure performance from plate to plate, lot to lot, and chemist to chemist.

By prepping and conditioning your plates, you will avoid having to rerun your sample or risk the decomposition of your compound. Follow these quick and easy steps:

- Always pre wash your TLC plate with either methanol or methanol/chloroform. Let plate sit overnight in a vent hood.

- To extract the prewashing, use the solvent system of choice for your sample and let this develop to the top of the plate. Again leave in a vent hood overnight.

- Next dry in a vacuum oven at 110°C for at least an hour. Let plate cool in vacuum oven until it reaches room temp. If not for immediate use, place plates in a desiccator to preserve.

TLC Plate Cutting Procedures

Cutting TLC plates enables you to run any size sample you want. By purchasing a large box of TLC plates and cutting them to a desired specification, you can save money, use less solvent, and customize your plate sizes.

Cutting Plastic or Aluminum Backed TLC Plates

- Keep plates as dry as possible before attempting to cut.

- Use sharp scissors and cut at a 45 degree angle leaning outside. So for instance, if you are right handed, tilt the scissors to the right.

- Don’t tilt scissors to the left – tilt scissors to the right. Tilting left causes flaking where tilting to the right will result in a sharp edge rather than a jagged edge.

Cutting glass-backed TLC Plates

Sorbtech TLC plate cutter (Cat#TLC-CUTTER) to enable a perfect cut every time without losing coating and eliminating waste.

Thin Layer Chromatography (TLC) and TLC Plates: Principles, Methodology, and Applications

Abstract

Thin Layer Chromatography (TLC) is a rapid, versatile, and cost-effective separation technique widely used in analytical chemistry. This article introduces the principles of TLC, explains the methodology, and highlights the critical role of TLC plates. In addition, it explores TLC’s applications in pharmaceuticals, food safety, environmental monitoring, and natural product chemistry. As a result, readers will understand why TLC remains an essential tool for both qualitative and quantitative analysis.

1. Introduction

Thin Layer Chromatography (TLC) is a fundamental analytical technique employed to separate, identify, and analyze complex mixtures. Because of its simplicity and reliability, it is used extensively in laboratories worldwide. This article not only introduces the basics of TLC but also emphasizes the importance of TLC plates, discussing their design, preparation, and wide-ranging applications in scientific research and industry.

2. Principles of Thin Layer Chromatography

TLC operates on the principle of partition chromatography. A sample separates because its components interact differently with the stationary phase and the mobile phase. A TLC plate, coated with an adsorbent material such as silica gel or alumina, serves as the stationary phase. Meanwhile, a solvent or solvent mixture functions as the mobile phase, carrying the compounds upward through capillary action.

As each compound demonstrates unique interactions with the stationary phase, they migrate at different rates. Consequently, the separation provides valuable insight into the sample’s composition.

3. TLC Plates: Composition and Types

TLC plates consist of a thin layer of adsorbent material adhered to a rigid or flexible support such as glass, aluminum, or plastic. Most commonly, silica gel and alumina are used as adsorbents.

There are two main types of TLC plates:

- Pre-coated plates – commercially available and ready to use.

- Homemade plates – prepared by applying an adsorbent slurry to a support surface and allowing it to dry.

Moreover, different plate types provide distinct separation characteristics, making it possible to tailor the analysis for specific applications.

4. Methodology of TLC Analysis

The methodology of TLC is straightforward yet powerful. First, the analyst spots the sample at a defined position near the base of the TLC plate. Next, the plate is placed in a solvent-filled chamber. As the mobile phase rises by capillary action, it transports the sample components.

When separation is complete, visualization techniques—such as UV light inspection or chemical staining—reveal the individual spots. Therefore, TLC provides a clear “fingerprint” for identifying and comparing compounds.

5. Applications of Thin Layer Chromatography

5.1 Qualitative Analysis

TLC excels in qualitative analysis, since the migration pattern of each compound serves as a reliable fingerprint for identification.

5.2 Quantitative Analysis

Although TLC is not as precise as advanced quantitative techniques, it can provide semi-quantitative results. By comparing spot intensities to known standards, analysts can estimate concentrations quickly and cost-effectively.

5.3 Pharmaceuticals and Drug Analysis

In the pharmaceutical industry, TLC plays a vital role in quality control. It helps confirm the presence of active pharmaceutical ingredients (APIs), detect impurities, and support forensic investigations of controlled substances.

5.4 Food and Beverage Industry

TLC is an important tool for ensuring food safety and quality. It helps detect additives, contaminants, and adulterants, thereby protecting consumers and maintaining regulatory compliance.

5.5 Environmental Monitoring

Environmental scientists rely on TLC to screen samples for pollutants, pesticides, and chemical contaminants. As a result, TLC contributes to environmental safety and ecosystem health assessments.

5.6 Plant and Natural Product Chemistry

Researchers studying herbal medicine and phytochemistry frequently use TLC to analyze plant extracts. It allows for quick identification and quantification of bioactive compounds in natural products.

6. Future Directions and Advances in TLC

TLC continues to evolve with new adsorbents, modified stationary phases, and improved visualization techniques. Furthermore, coupling TLC with spectroscopic methods (such as mass spectrometry) greatly enhances compound identification and expands its applications in modern research.

7. Conclusion

Thin Layer Chromatography remains a powerful, simple, and adaptable tool in analytical chemistry. By combining the use of TLC plates with proven methodology, researchers achieve both qualitative and quantitative insights. Therefore, whether applied in pharmaceuticals, food safety, environmental science, or natural product chemistry, TLC continues to provide efficient, accurate, and reliable separation solutions.