Process Chromatography in Plastics Recovery

Problem

Over the past 70 years, plastic production—and the disposal of plastic products—has expanded so rapidly that it now creates a global pollution crisis. Today, industries manufacture more than 400 million tons of plastic every year, and this constant output puts tremendous pressure on the planet’s ecosystems.

Although many cities run recycling programs, landfills and oceans continue to overflow at alarming rates. Each year, about 13 million tons of plastic wash into the oceans, and experts expect that number to climb nearly tenfold by 2025. When plastic waste enters the environment, it never truly disappears. Instead, it gradually breaks down into tiny fragments called microplastics. These particles now show up in fish that people eat, in seabirds, and throughout the food chain. Because a single piece of plastic can take as long as 450 years to decompose, the problem steadily grows worse. Clearly, this is a crisis that demands immediate action, not one that will fade away on its own.

To meet this challenge, researchers and industries are turning to new technologies. One promising pathway focuses on pyrolysis oil processes, which convert plastic waste into usable energy. In this process, heat breaks down plastics without oxygen, producing gases and oils that can serve as fuel or feedstock for new products. However, to make pyrolysis work effectively at an industrial scale, the process requires specialized adsorbents and purification products. At the same time, companies still need to test these approaches for cost-effectiveness and long-term benefits. As a result, the field remains full of challenges but also full of opportunities for innovation and progress.

Solution

A growing effort is underway to convert plastic waste into valuable resources using a process called pyrolysis. In this method, plastic waste is heated in the absence of oxygen, causing the material to break down into simpler chemical compounds. These compounds release usable gases, which can then be directed into further refining steps.

Through a process known as biomass gasification, heat and steam transform this material into hydrogen and other valuable outputs. The final product is a reusable crude oil that can serve as a fuel source or as feedstock for manufacturing new plastics.

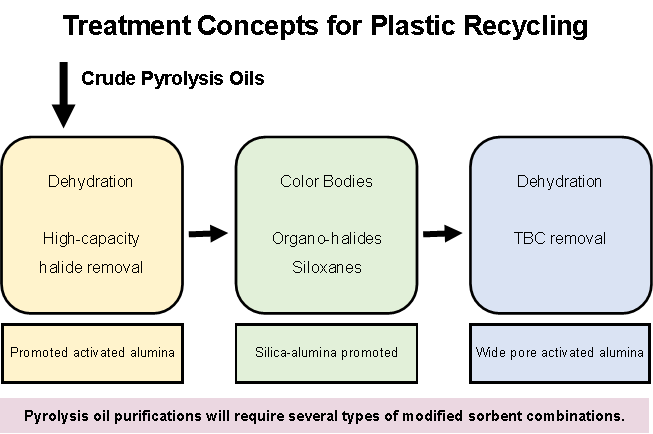

To make this process work on an industrial scale, target-specific adsorbents are essential. These purification materials play a critical role in removing impurities, stabilizing output streams, and improving the quality of pyrolysis oils. In the illustration below, we present several of our purification sorbent concepts, designed to meet the unique challenges of processing oils derived from plastic waste. By applying advanced sorbent technologies, we can help transform plastic waste into a cleaner, more sustainable resource for the future.

Types of possible sorbent modifications available for plastics recycling applications

Size

Shape

Crystallinity

Porosity

Surface Area

![AdobeStock_136264682 [Converted] Treatment Concepts for Plastic Recycling](https://www.sorbtech.com/wp-content/uploads/2022/04/AdobeStock_136264682-Converted.png)

Thermal stability

Acid/Basic Chemistry – Lewis & Bronsted

Surface Charge

Activity

Selectivity

Sorbent Technologies is committed to developing and optimizing sorbent materials for plastic recycling and in generating an application database for this purpose.

Schedule a phone or video conference with your Account Manager to discuss in more detail.

The information contained in this data sheet is believed to be true and accurate but is presented for guidance only. Risks and liability for use of the products or application of the suggestions described are assumed by the user. Any recommendations or suggestions are made without warranty or guarantee.